There are certainly a lot of benefits to having piston oil squirters / jets, which came stock on the turbo 6G72 DOHC engines. They help cool the stock cast piston and most likely help with wrist pin and cylinder bore life.

The downside is the 2 center main journals already feed 4 rods and themselves and we are also asking them to feed 4 jets that are in theory closed below 30 PSI.

The issue to me, personally, is that its impossible to tell what the localized flow/pressure is in the oil system at those 2 center mains and they almost always seem to be worn worse than the outside too.

There are some steps that could be taken to help equalize this flow, such as restrictors on the outside 2 main bearing journal feeds or boring out the center two feeds, but those are outside the scope of this post.

Since we have forged pistons in the Stealth shop car, we are going to eliminate the oil squirters in order to save more of our oil flow for the bearings.

There is obviously more than one way to do this (you could weld shut the squiters for instance), but we felt really comfortable doing it this way. Its cheap and easy and requires no special parts.

Preparation

You will need to have your crankshaft removed for this operation, so your best bet is to do this while you are doing other work.

It is critical to cover your main bearing journal feeds with some tape as this is going to create some shavings. Be careful and clean your engine carefully when done.

It is critical to cover your main bearing journal feeds with some tape as this is going to create some shavings. Be careful and clean your engine carefully when done.

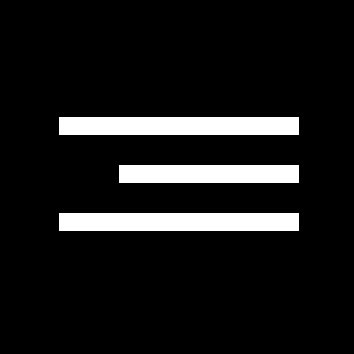

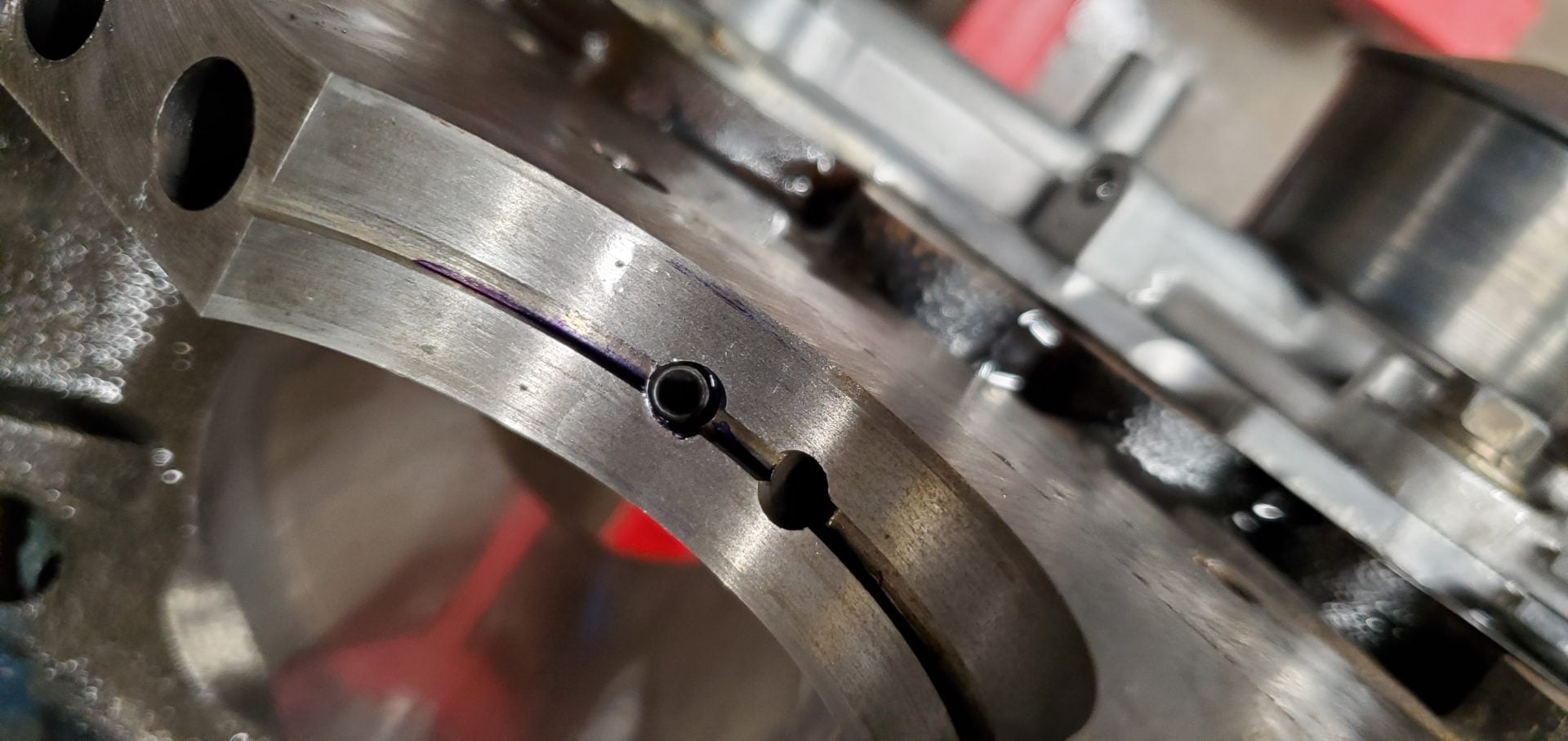

We apologize we don’t have a pic of knocking these out, but these are the squirters. Use a long punch and knock them out from the top after removing the pistons.

We apologize we don’t have a pic of knocking these out, but these are the squirters. Use a long punch and knock them out from the top after removing the pistons. You will need a fresh 1/4 – 20 tap. Coat it with grease to capture as many shavings as you can and clean between uses.

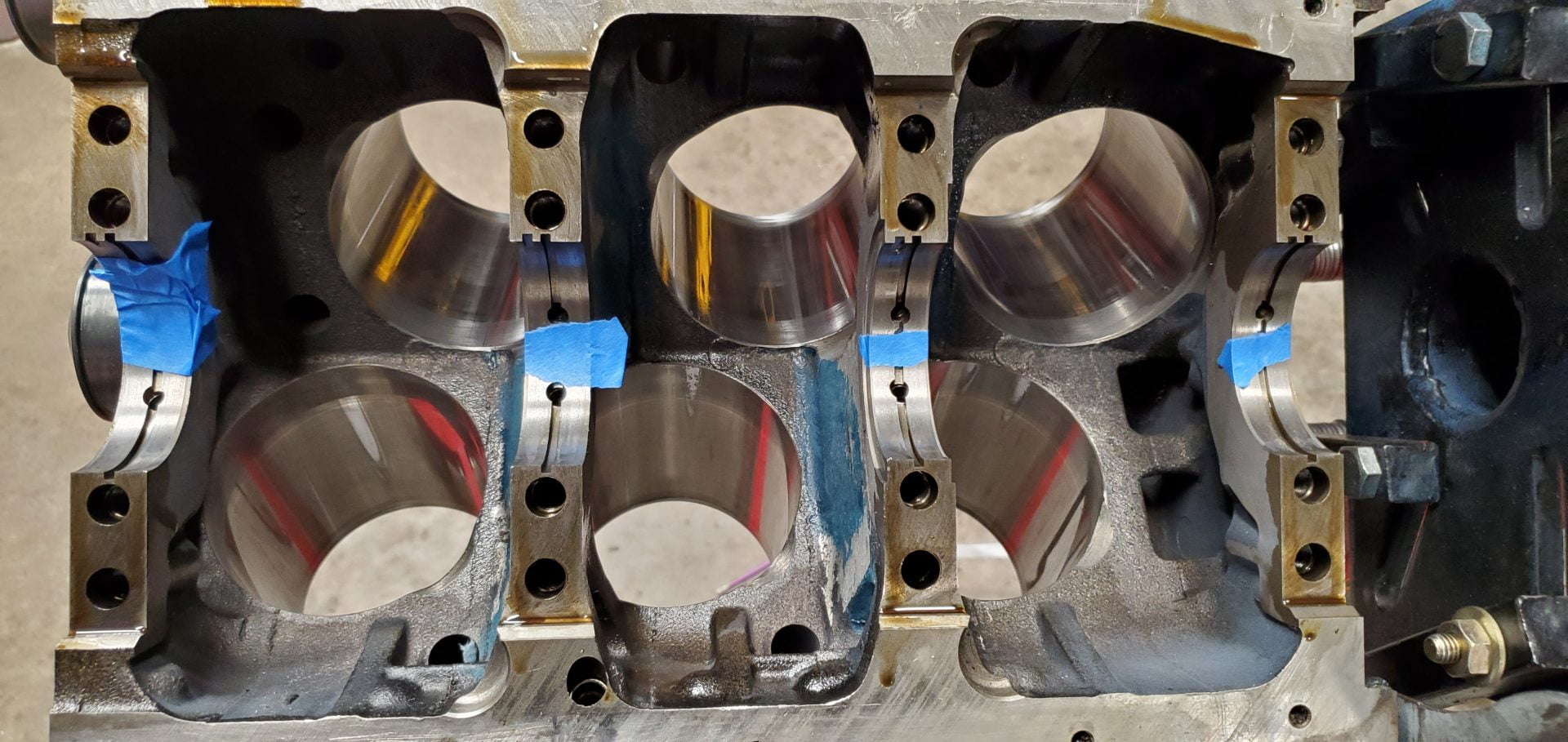

You will need a fresh 1/4 – 20 tap. Coat it with grease to capture as many shavings as you can and clean between uses. Carefully tap the squiters holes. Be sure they are the SQUITER holes and not the main journal feeds or you will lock your engine up instantly. The tap will be at an angle, because that is the direction the jets pointed. Be careful and back off every half a turn. You DO NOT want to break a tap off in your block.

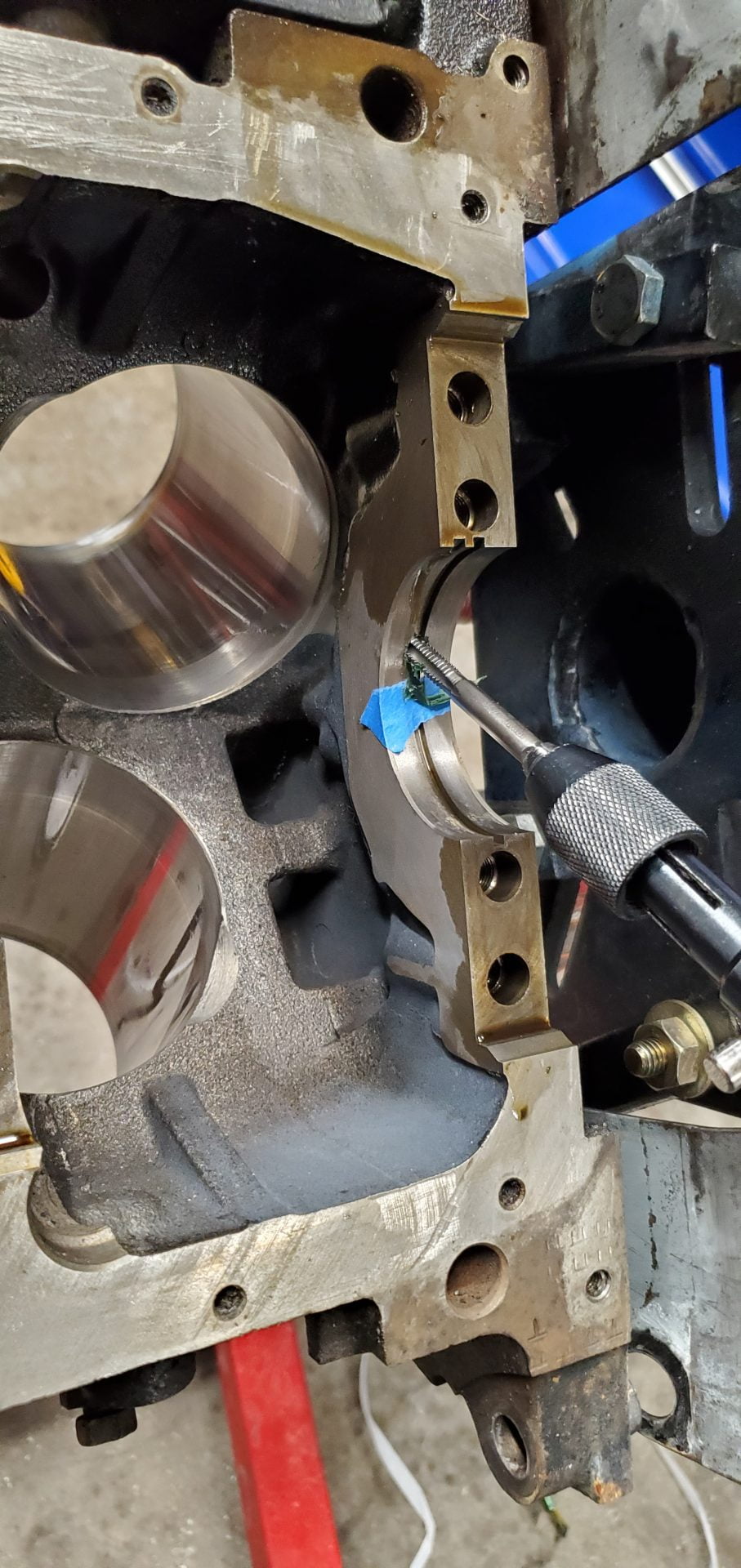

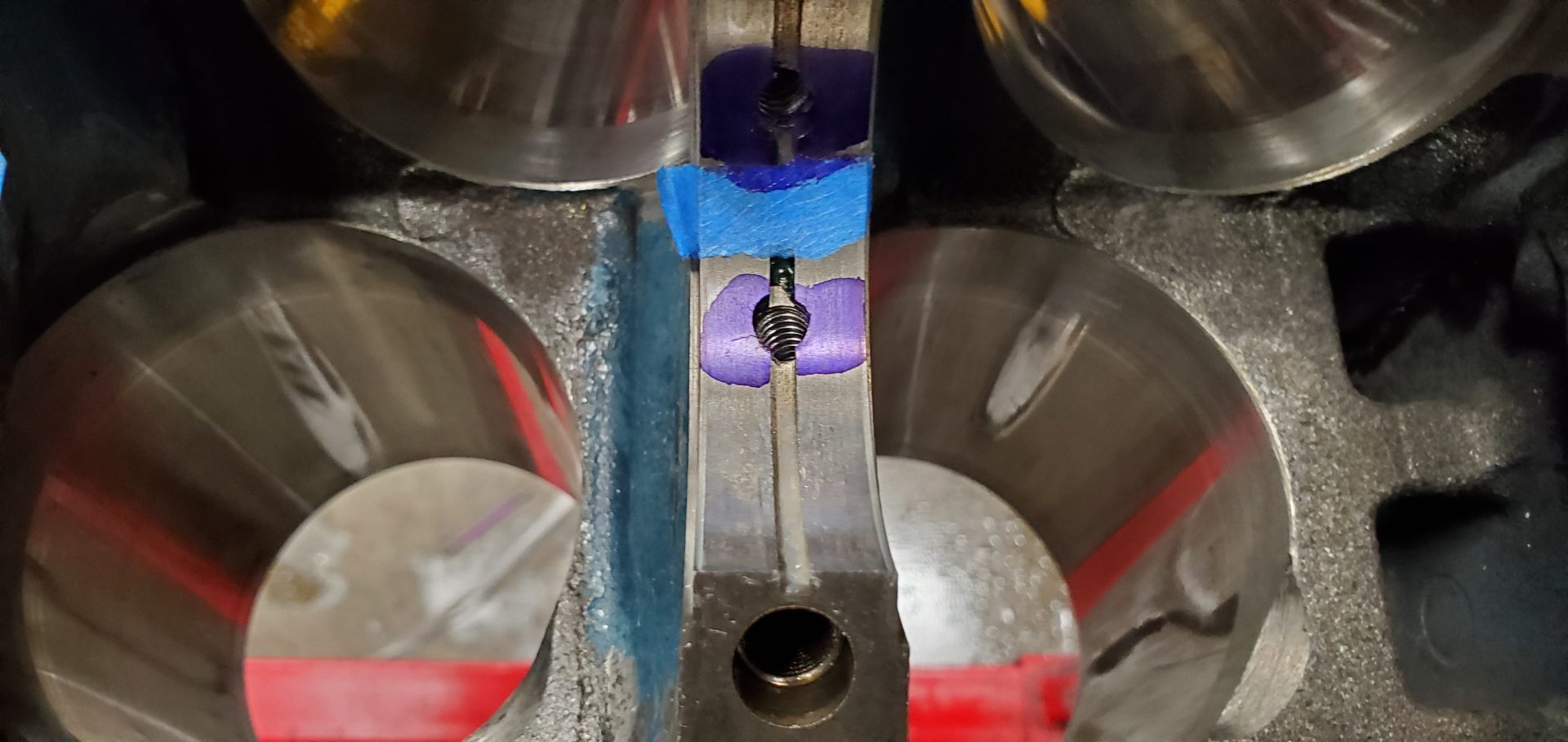

Carefully tap the squiters holes. Be sure they are the SQUITER holes and not the main journal feeds or you will lock your engine up instantly. The tap will be at an angle, because that is the direction the jets pointed. Be careful and back off every half a turn. You DO NOT want to break a tap off in your block. When you are done you should have nice threads like this.

When you are done you should have nice threads like this. Have some layout fluid, it will help with the next step.

Have some layout fluid, it will help with the next step. Get a sharpening/honing stone.

Get a sharpening/honing stone. Put some layout fluid around the hole you just tapped and let it dry.

Put some layout fluid around the hole you just tapped and let it dry. Slowly run the hone back and forth parallel to the main cap until you are sure any burrs from taping are gone. A high spot here will ruin your bearing. Do not try to remove any material from the block, we are just trying to get rid of any high spots.

Slowly run the hone back and forth parallel to the main cap until you are sure any burrs from taping are gone. A high spot here will ruin your bearing. Do not try to remove any material from the block, we are just trying to get rid of any high spots. Get some 1/4 – 20 set screws. 3/8 or 1/2 deep works great. Coat them in RED or GREEN high strength thread locker.

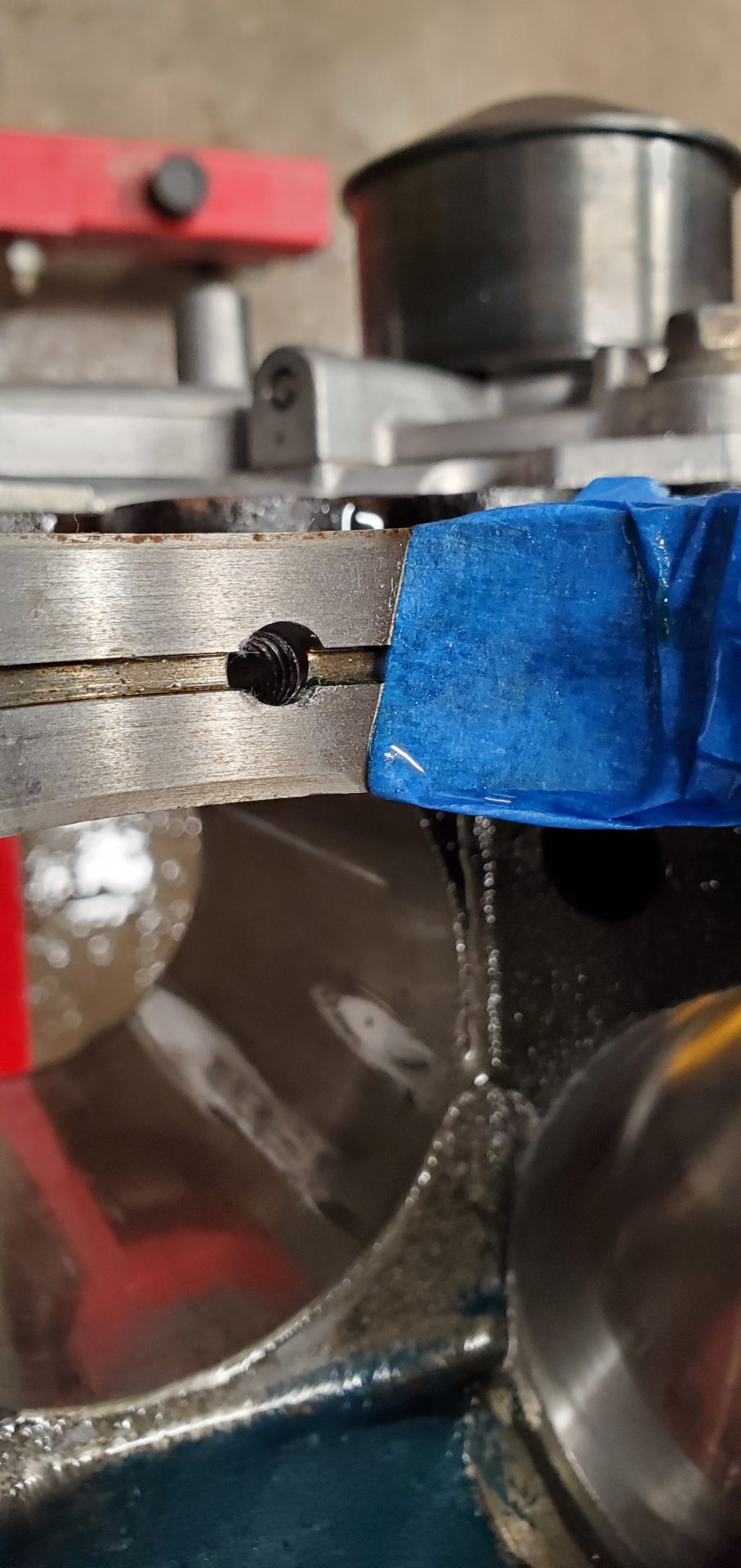

Get some 1/4 – 20 set screws. 3/8 or 1/2 deep works great. Coat them in RED or GREEN high strength thread locker. Screw it in carefully until it bottoms out, make sure you don’t block the flow of oil by having it above the bottom of the groove.

Screw it in carefully until it bottoms out, make sure you don’t block the flow of oil by having it above the bottom of the groove. Clean it all up and do it 6 times and you are done!

Clean it all up and do it 6 times and you are done!